International Steel Framing’s Performance 1 is an automatic, multiple profile, gearbox driven roll forming machine — that changes profiles in about 5 minutes and automatically adjusts to do multiple gauges — making it the most cost-effective roll former on the market today.

Performance 1

- Minimizes changeover time and keeps training time to a minimum

- Automatically adjusts from 22- to 14-gauge (.030” to .075”)

- Reduces profile change times by 90%.

- Increases accuracy and minimizes downtime

Time-Saving Technology

ISF’s roll formers are designed for ease of changeovers by taking a semi-automated approach.

Performance 1 has a manual cranking system that moves all of the roller stations simultaneously. This technology is a game-changer because the time and cost of making a change are nearly trivial. From a design standpoint, Performance 1 makes it feasible to consider any number of different profiles and engaging combinations.

Gearbox vs Chains

Most multiple profile roll forming machines are chain-driven. The problem is that chains break (especially with heavier gauge material.) When chains break, production stops. And even when chains don’t break, they loosen over time. Loose chains require machine operators to constantly check the length of pieces coming off the machine and often stop for manual adjustments.

Performance 1:

- Uses a gearbox system

- Requires less maintenance

- Doesn’t break

- Needs no calibration

- Has fewer problems requiring a technically adept operator

Build More

Constructing trusses and walls in the United States and addressing midrise construction markets, can’t be done with a roll forming machine that only allows for building up to 50-feet.

Performance 1 gives the flexibility to go out to wider spans and build up to eight stories. ISF roll forming machines go from a two-and-a-half width to an eight-inch — and everything in-between — (including the occasional oddball job when someone wants a five-inch member.)

Spend Less

Along with its complete profile flexibility — Performance 1 can also vary the flange — which saves money.

By varying the flange, it can also vary the strength of the member by making it wider. So, if greater strength isn’t needed, it uses less steel. Conversely, ISF’s offering is flexible enough to go from as little as one-and-five-eights-inch to a three-inch flange width – all in one machine – with the ability to go anywhere from 22- to 14- gauge and be used in any width.

Performance 1

General Specifications

- Material: Galvanized and Cold Roll Steel (CRS) 32 to 66 KSl (221 to 455 MPA)

- Gauges: from 22 GA (.030”) to 14 GA (.075”)

- Tensile Strength: 32 KSI to 66 KSl (221 MPA to 455 MPA)

- Part Size: 2 ½” to 8” (6.35 to 20.32 CM) to Cee Sections Studs and U Sections for Track

- Flange size: 1 5/8” and 2” (4.13 and 5.08 CM)

- Line Speed: Variable depending on the punching patterns. Plain track may run up to 120 FPM (36.57 MPM)

- Approx. gross weight: 25,000 LBS (11 340 KG) includes De-coiler, Leveler, Punch Presses and Roll Former

Section Applications

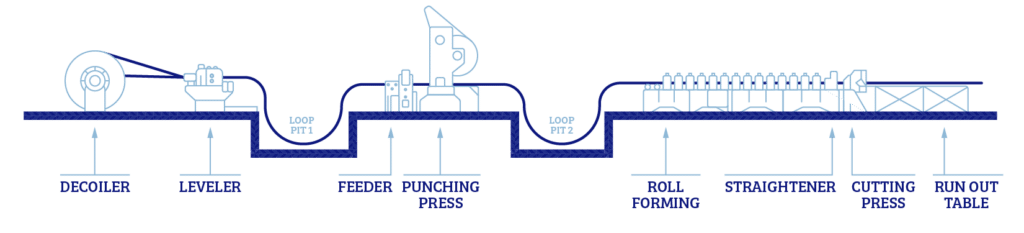

- Dual Arm Decoiler: Hydraulically driven. The dual-arm decoiler holds two coils of up to 6,000 pounds (2 722 KG) at all times and expands the mandrel using hydraulics, (no manual cranking!), and holds the coil, also generates back tension while rotating.

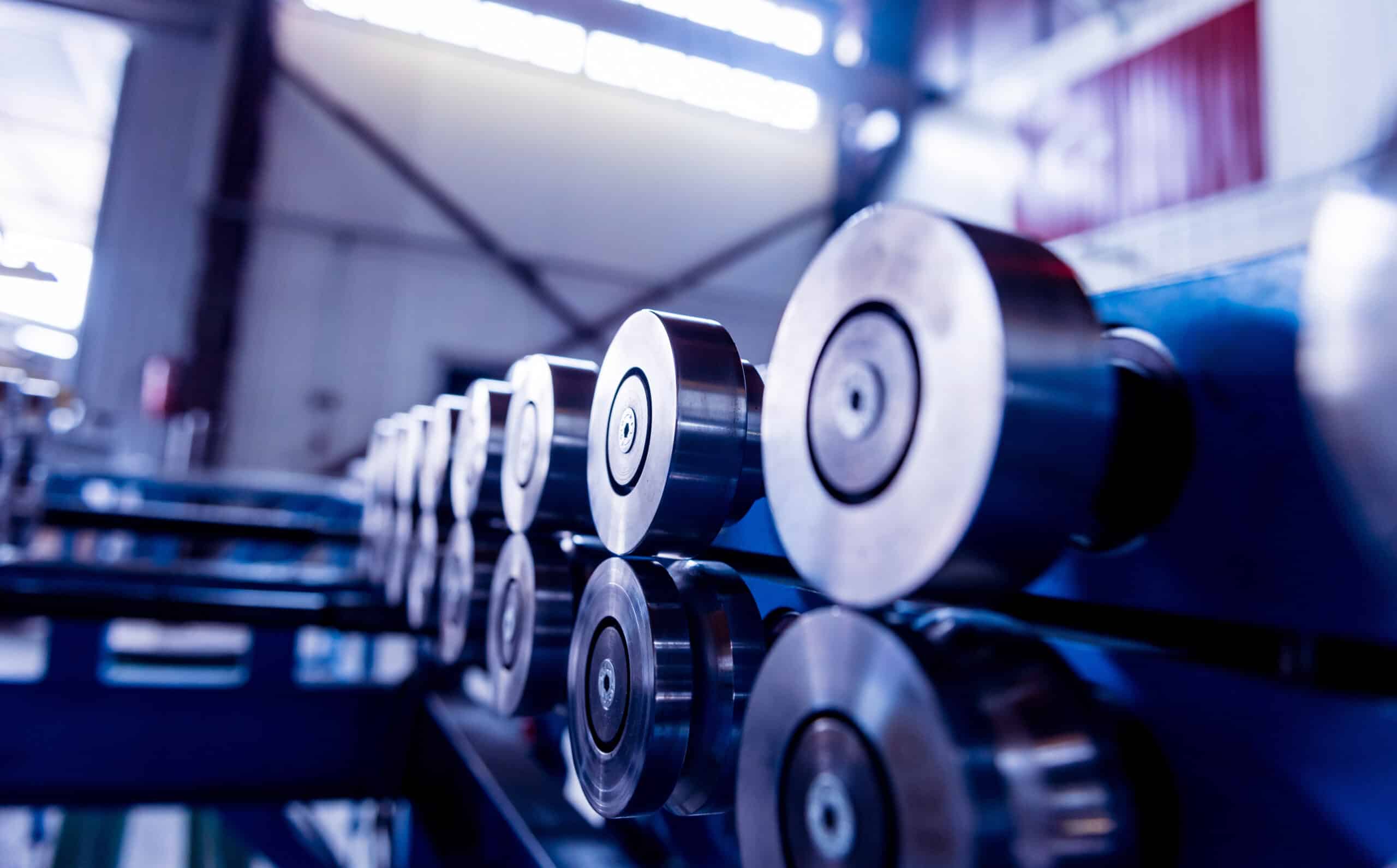

- Coil Leveler: Pinch rollers pull coil stock from decoiler, leveling rollers remove coil, then set and flatten the material.

- Loop System: Synchronizes line speed to avoid tension or stretch of the material processed.

- Feeder: Used to feed precise length of coil stock to the punch press or shear. Pulls material from loop and stops at desired pitch.

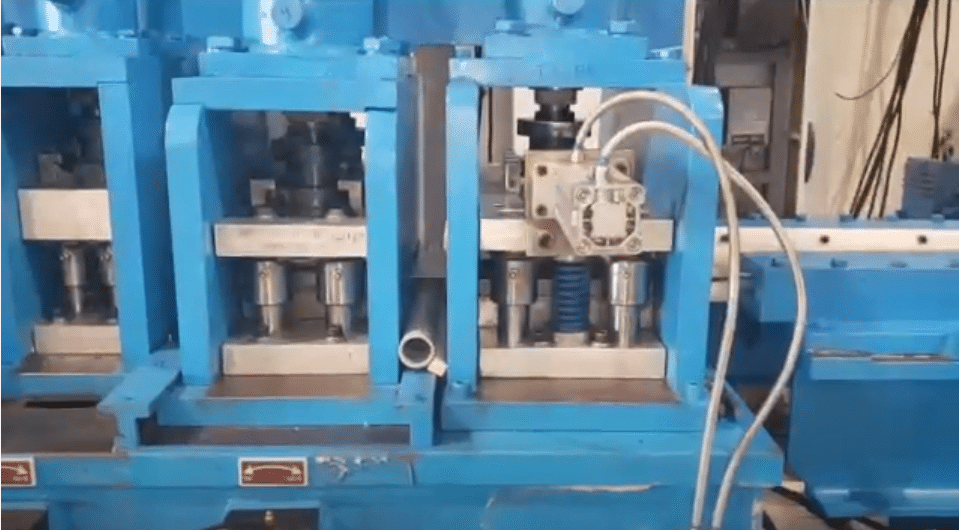

- Width Wise Adjustable C Punch Presses: Pre-punchs coil stock, suitable for blanking, slight embossing, piercing, coining, and perforation.

- Rollformer: 11 stations duplex with split tooling. Horsepower: 30 HP (22.4 KW)

- Runout Conveyor: 118” (299.72 CM) conveyor with max weight capability of 46 LBS (21 KG)