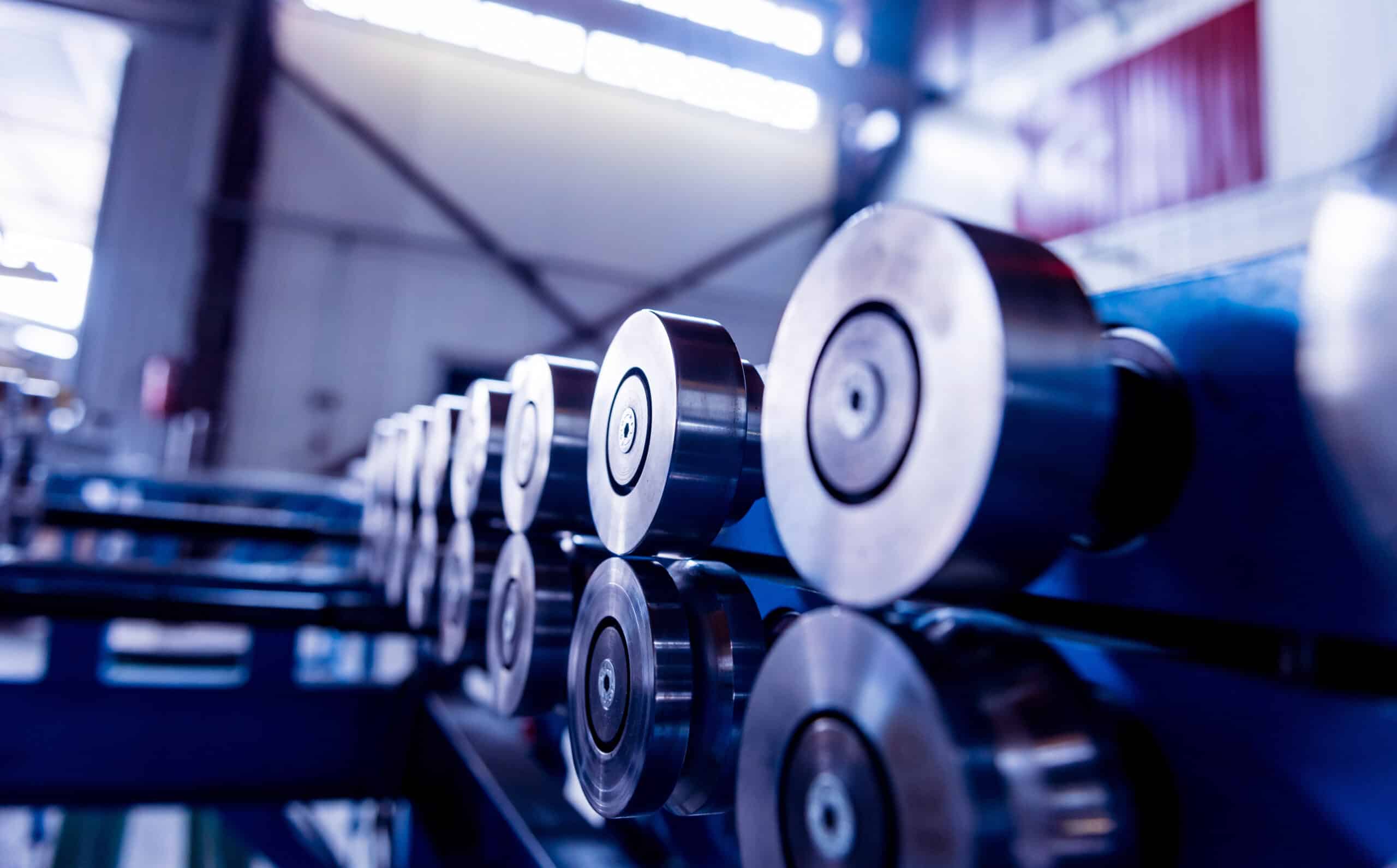

Different types of steel are good for different applications. During the creation process, steel can be hot-rolled or cold-rolled. Both hot-rolled steel and cold-rolled steel have their unique advantages and disadvantages. For construction, cold-formed steel (CFS) is generally better than hot-rolled steel.

However, cold-formed steel has the upper hand in architecture compared to other materials like lumber, hot-rolled steel, and plywood. Cold-formed steel is cost-effective, non-combustible, precise, and environmentally friendly.

Cost-Effectiveness

According to The Steel Network, lumber prices rose just over 60% in 2021, while cold-formed steel prices only rose 20%. As the global population increases, lumber prices continue to rise, making CFS much more cost-effective for building more homes and apartment buildings to accommodate.

Insurance and maintenance costs on homes made from steel are much lower compared to other materials. The risk of damage from outside sources is much higher with timber and plywood than when steel is used. This makes wooden structures a riskier investment for home insurance companies.

Non-combustible and Sturdy

The elements are always a risk to consider with buildings. According to c2es, the occurrence of wildfires doubled from 1984 to 2015 in the United States. As wildfires become more common, home insurance prices on wooden buildings continue to rise.

Cold-formed steel buildings also resist structural damage from natural disasters and extreme weather, such as:

- Heavy winds

- Earthquakes

- Heavy snowstorms

- Lightning strikes

CFS is also advantageous because it is completely impervious to mold, rot, and mildew. Vermin, such as termites and ants, can’t chew through it. All of these factors come into play when insurance companies are calculating coverage. Consequently, steel is less costly to insure.

Precision

Another advantage of cold-formed steel is that it is precise.

Hot-rolled steel changes its form as it is cooled. This leads to the steel’s shape-changing as its edges round out and it shrinks. Wood can also change shape if it rots or absorbs moisture, weakening structural support. CFS has neither of these problems.

CFS has completely accurate measurements. Compared to wood and hot-rolled steel, cold-formed steel is much smoother, doesn’t expand or contract, and is perfect for projects that require exact measurements, such as buildings and bridges.

Environmentally Friendly

Steel framing is made from an average of 67% recycled material. In addition to this, steel is 100% recyclable. Once steel products reach the end of their lifespan, they can be reused in different applications an infinite number of times, unlike wood or plastic, which can only be used once.

Ready to Harness the Benefits of Cold-Formed Steel?

International Steel Framing is the leading single-vendor solution for everything needed to succeed in the cold-formed steel industry. To learn more, contact us today.