When making the decision to purchase a roll forming machine, it’s a good idea to perform a cost/benefit analysis to gain some insight into potential revenues, costs, and profitability margins.

This process involves analyzing two product lines: wall panels and stud and track materials for most companies.

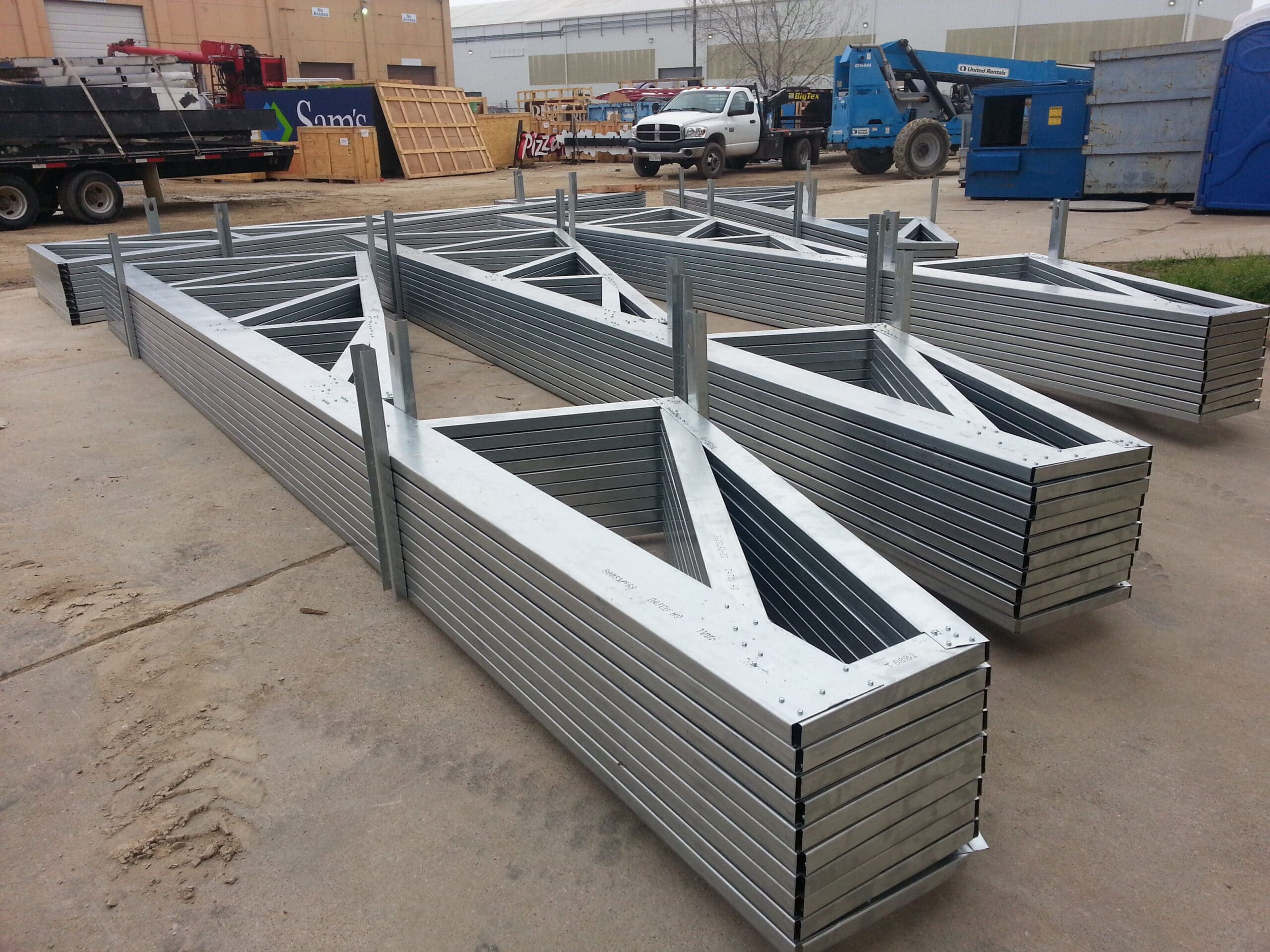

However, there is a third potential revenue line in manufacturing light gauge steel trusses.

While there are a variety of options out there for steel truss design systems, the KeyTruss system stands out for its material efficiency, cost-effectiveness, and money-saving (and making) potential.

What is the KeyTruss Design System?

KeyTruss is the latest revolution in cold formed steel Cee-truss design technology.

With automation capabilities for each process step, KeyTruss can expedite everything from design and fabrication to shipping and installation, saving companies up to 30% on Cee-truss designs alone.

The secret is in the tight integration between computer-guided roll formers and state-of-the-art software for trusses that are intricately and expertly engineered with both sustainability and durability in mind.

Material Efficiency

The KeyTruss system has been developed to save on materials wherever possible.

All KeyTruss pieces are cut to length, eliminating waste materials and the need for stock inventory and storage space.

KeyTruss pieces are also designed to:

- Reduce the need for gusset plates by providing plenty of space for screws between webs and chords

- Reduce the necessity for lateral bracing and web stiffeners

Cost-Effectiveness

KeyTruss is also designed for maximum cost-effectiveness and savings when it comes to the following:

- Assembly – A reduced need for gusset plates and bracing, as well as single-sided screw connections and coped flanges, make for faster and easier assembly in the field.

- Shipping – The single-ply in-line design of KeyTruss pieces cuts shipping volume in half compared to other traditional trusses.

- Installation – With drop-off at predetermined points and orientation markings, the installation of KeyTruss pieces is smoother and faster than other truss designs.

Money Making Potential

Along with the savings mentioned above, the KeyTruss system can maximize earning potential through cost savings on steel.

The current LGS truss market is dominated by two proprietary parts suppliers who charge about $.85/lb over the price/lb for steel coils.

At International Steel Framing, we charge only a $.10/lb markup on steel costs.

With labor costs almost equal to the cost of the roll forming parts (and a small 17% increase in steel use), the result of using KeyTruss is a $.50/lb advantage.

Ready to Maximize Your Revenue with KeyTruss?

If you are going to invest in a roll forming machine, including truss manufacturing with the KeyTruss system can substantially increase your revenue potential.

Contact us at International Steel Framing today to learn more about KeyTruss and our other offerings.