An Introduction to Roll Forming

Roll forming is a cost-effective manufacturing process that shapes metal coils into custom-designed profiles. This cold-formed method has found widespread application in various industries, offering a streamlined approach to creating structures, beams, columns, and sections.

In this blog, we will delve into the fundamentals of roll forming, exploring its processes, benefits, and uses that make it a preferred choice in metal fabrication.

Understanding Roll Forming

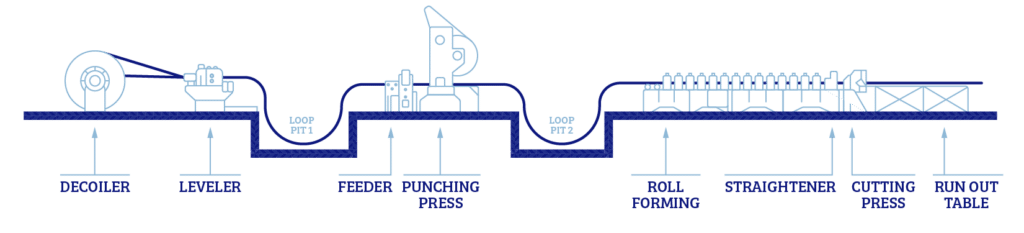

Roll forming is a continuous bending process that transforms metal coils into complex shapes. The process involves passing a metal strip or coil through a series of rollers, each set designed to bend the material into the desired profile incrementally. The roller sets are strategically positioned to gradually shape the metal, with each set forming a specific part of the final profile, including studs, joists, trusses, and other components.

Roll forming machines have computer-controlled systems that monitor and adjust various parameters, such as roller positions and speeds, to ensure accuracy and repeatability. This automation enhances precision and allows for rapid production rates, making roll forming an efficient method for large-scale manufacturing.

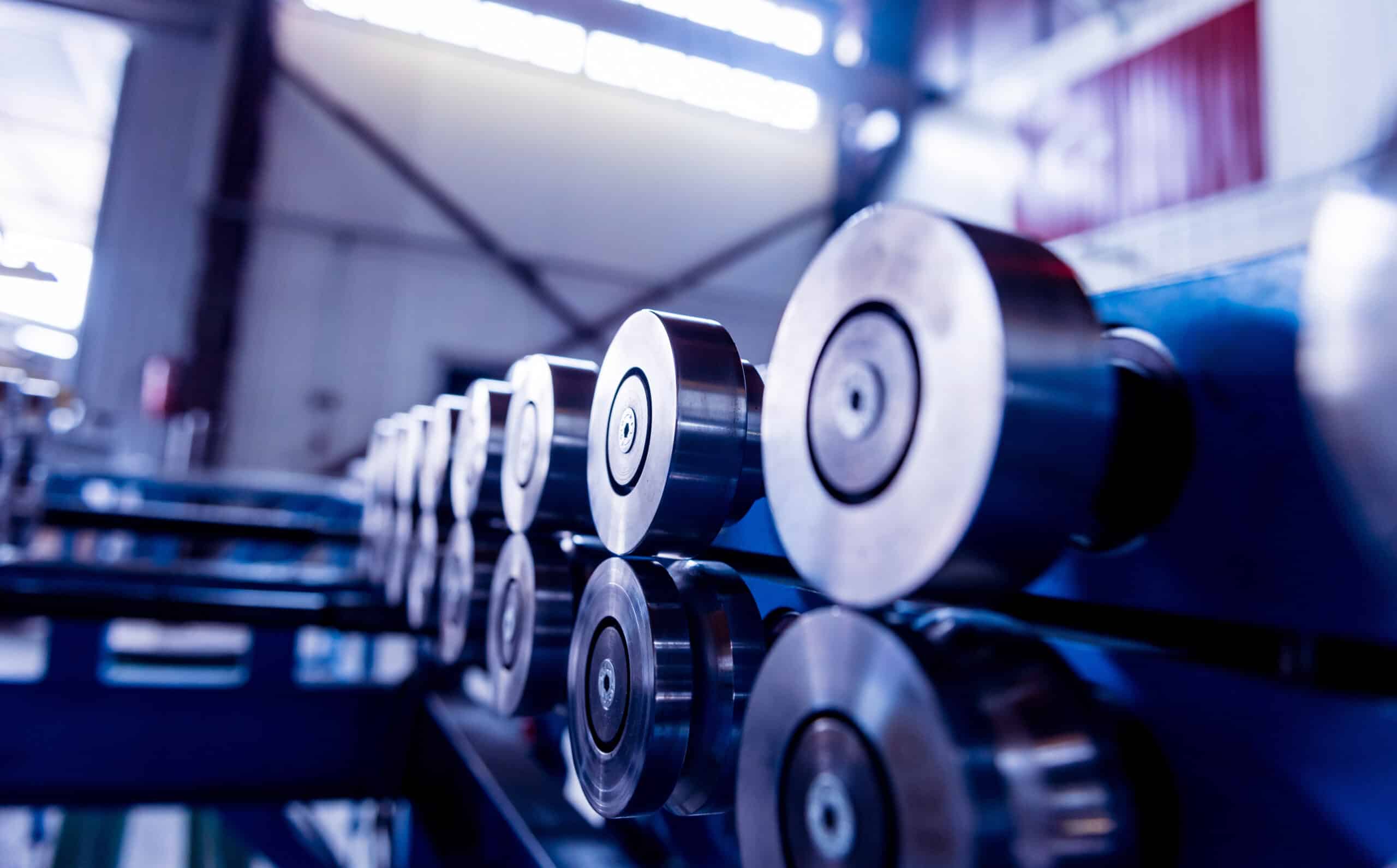

Here is an International Steel Framing roll former in action!

Benefits of Roll Forming

Roll forming offers many benefits that contribute to its use in various industries. One of its key advantages is in cost-effective production. By minimizing material waste and reducing the need for secondary operations, roll forming results in significant cost savings for materials and labor. Further savings come from roll former machines that accommodate different flange widths and gauges, adding to the overall economic viability of the process.

The automated nature of roll forming brings about other advantages—high precision and consistency. The process ensures that metal profiles are produced accurately, meeting stringent quality standards. This level of precision is maintained consistently across large production runs, giving manufacturers the confidence that each product adheres to the specified dimensions and tolerances.

Roll forming’s versatility in design is a standout feature. It enables the creation of a wide array of intricate profiles, ranging from simple beams to complex structural components. Designers benefit from this flexibility, as it allows them to tailor products to specific requirements and aesthetic preferences. This adaptability positions roll forming as a go-to method for industries requiring custom-designed metal profiles.

Efficiency is another advantage of roll forming. The process optimally uses the entire length of the metal coil, minimizing scrap and maximizing material efficiency. This contributes to environmental sustainability by reducing waste and enhancing the manufacturing process’s cost-effectiveness. In addition, the roll forming process is more rapid and takes less energy than extrusion.

Applications of Roll Forming

With its numerous benefits, roll forming has earned its place as a fundamental process with widespread applications across many industries. Roll-formed metal profiles are pivotal in creating beams, structures, and other components in the construction sector, offering durability and precision. The automotive industry uses roll forming for producing components like chassis elements and body panels, benefiting from the method’s cost-effectiveness and efficiency.

In aerospace, manufacturing, appliance, agriculture, and solar industries, the versatility of roll forming creates custom-designed profiles. The wide range of applications highlights the adaptability of roll forming in shaping the metal components that form the backbone of many industrial sectors.

Ready To Take Advantage of Roll Forming?

You’ve designed the trusses, submitted the orders, waited for the supplier to roll form the parts for each one, and then incurred the high freight and remote manufacturing costs. When your deliveries finally arrived, the parts weren’t all cut to length and didn’t have intelligent markings, so you had to pay your employees to unload the trucks, measure, mark, cut the pieces, and do the jigging for assembly.

If this scenario sounds familiar, check out the benefits of International Steel Framing Performance 1 roll formers and get in touch!