Off-site construction of cold-formed steel framing refers to the process of manufacturing and assembling building components made from cold-formed steel (CFS) in a controlled factory environment, away from the actual construction site. This approach is also known as prefabrication or modular construction. Cold-formed steel is formed at room temperature, typically through roll-forming machines, into various shapes and profiles that are used as structural members in buildings.

Off-site construction, including cold-formed steel framing, has gained popularity in recent years due to its many advantages, including cost savings, sustainability, and improved safety. Cold-formed steel framing can be used in almost any structure, from offices to multi-use apartments and even for residential homes.

Off-Site Construction of Cold-Formed Steel Framing

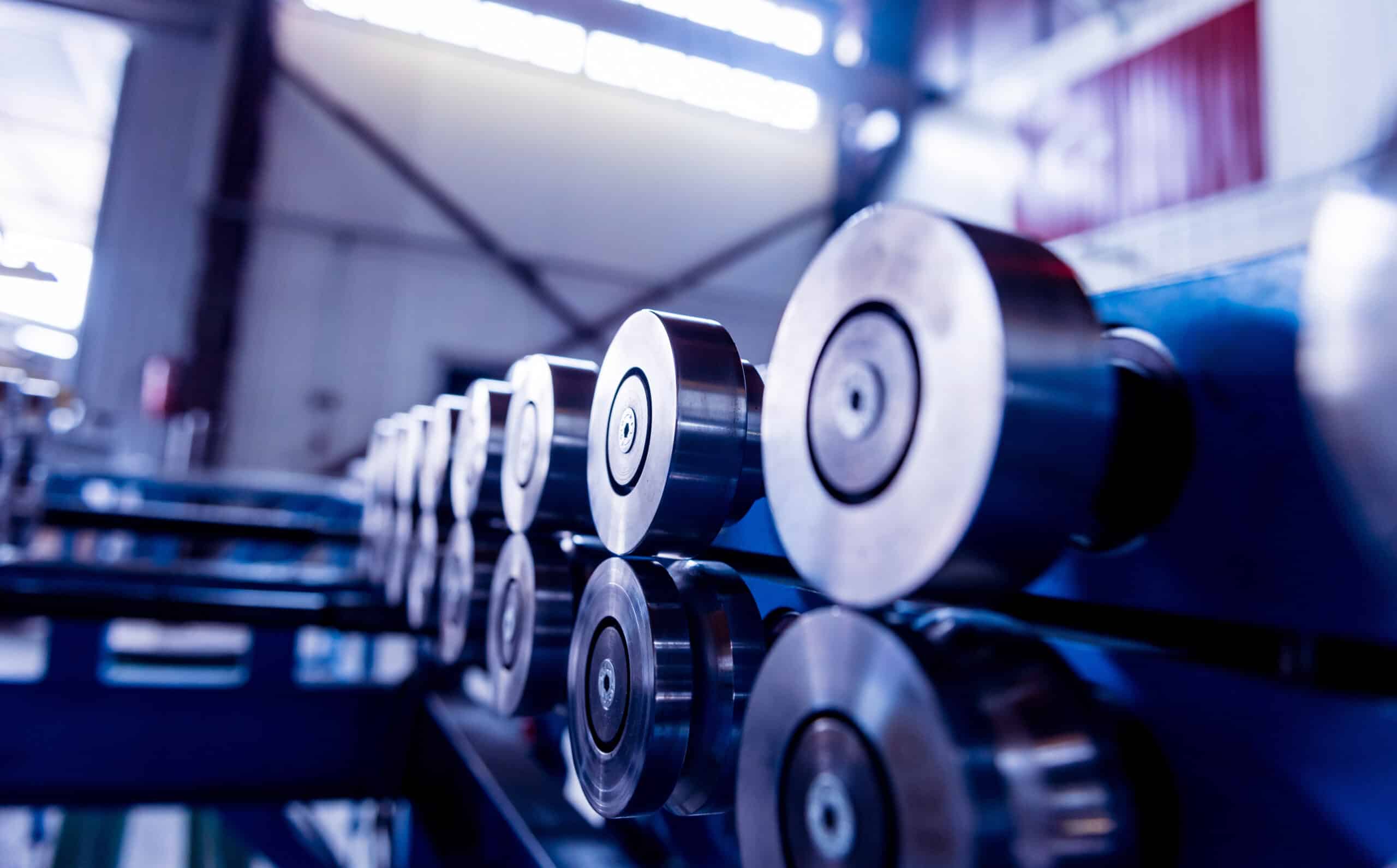

The building’s design is prepared using computer-aided design (CAD) software, taking into account the specific requirements and specifications of the project. In a factory setting, cold-formed steel sections are produced by feeding steel coils through roll-forming machines that shape the steel into the desired profiles, including studs, joists, trusses, and other framing components.

The pre-manufactured steel components are then assembled into larger panels or modules according to the design of the building. This process can include the addition of insulation, sheathing, and other necessary elements. During the manufacturing and assembly processes, strict quality control measures are implemented to ensure that the components meet the required standards and tolerances.

Once the components or modules are ready, they are transported to the construction site. Cold-formed steel’s lightweight nature allows for easy transportation and handling. Trucking panels under 8.5 feet wide from the fabrication facility to the job site usually do not require a special permit.

Cold-formed steel components are designed for efficient and quick installation. They fit together seamlessly with pre-engineered connections and standardized sizing, streamlining the construction process. At the construction site, the pre-fabricated steel components are erected and assembled according to the building’s design. This step involves connecting the components, fastening them together, and integrating other building systems like electrical and plumbing.

6 Benefits of Off-Site Construction of Cold-Formed Steel Framing

Benefits of off-site construction using cold-formed steel include:

- Faster Installation

- More Precision & Higher Quality

- Reduced Waste

- Cost Savings

- Sustainability

- Improved Safety

The off-site construction approach can significantly reduce overall construction time since many tasks are completed simultaneously, both on-site and in the factory. Additionally, factory-based assembly reduces on-site construction risks and improves worker safety. Lightweight, quick installation, low waste, and non-combustible nature of cold-formed steel helps to create a safer construction site.

Factory-controlled production ensures higher precision and consistency in the fabrication process, leading to higher-quality construction. Prefabrication allows for better material optimization, leading to reduced waste generation. While initial costs for cold-formed steel framing may be higher than traditional methods, the time savings and reduced labor costs result in overall cost savings. The fact that cold-formed steel is 100% recyclable and on-site construction waste is reduced contributes to a more sustainable building process.

Ready To Take Advantage of Cold-Formed Steel?

International Steel Framing is the leading single-vendor solution for everything needed to succeed in the cold-formed steel industry, from the ISF Software Suit to Keytruss cold-formed steel design technology and our roll formers designed for ease of changeovers.

Get in touch today to learn more!