Pole barns, also known as post-frame buildings, are popular for their versatility and affordability in construction. Advanced automation software and specialized roll-forming machinery have revolutionized how pole barns are designed and built, making the process easier and more efficient.

A Rollforming Magazine case study details just how easy it was to construct a 60’x140′ cold-formed steel pole-barn style building. Advanced automation software for building design and truss engineering combined with special roll-forming machinery created a new building system that went together in the field perfectly, with the combined cost of materials and field labor coming out to be less than a similar wood-framed pole barn.

Design and Planning

Complete pole barn structures can be designed and engineered using the ISF software suite, from foundation to roof and everything in between. Users start by creating a 3D structure model and then frame it to see how it will look. Next, Keymark tools can be used to develop and apply loads and automate the specification of load-resisting materials and components. After the design process, machinery interface files are generated to automate fabrication.

Steel framing is most efficient when using ISF’s Steel Construction Software. This steel framing software reflects all changes in the fabrication drawing, reducing the time-consuming process of manually updating design plans. Furthermore, the software program will estimate the required steel quantity and automatically produce a complete material cut list. The accurate estimate of materials required on the materials list helps reduce waste and optimize material usage. Advanced software allows for easy customization of pole barn designs to meet specific needs and preferences.

Once the design is finalized, the software generates automated quotes and bills of materials, making it faster and easier for contractors and customers to receive accurate project costs. Maximizing revenue has never been easier!

Precision Manufacturing

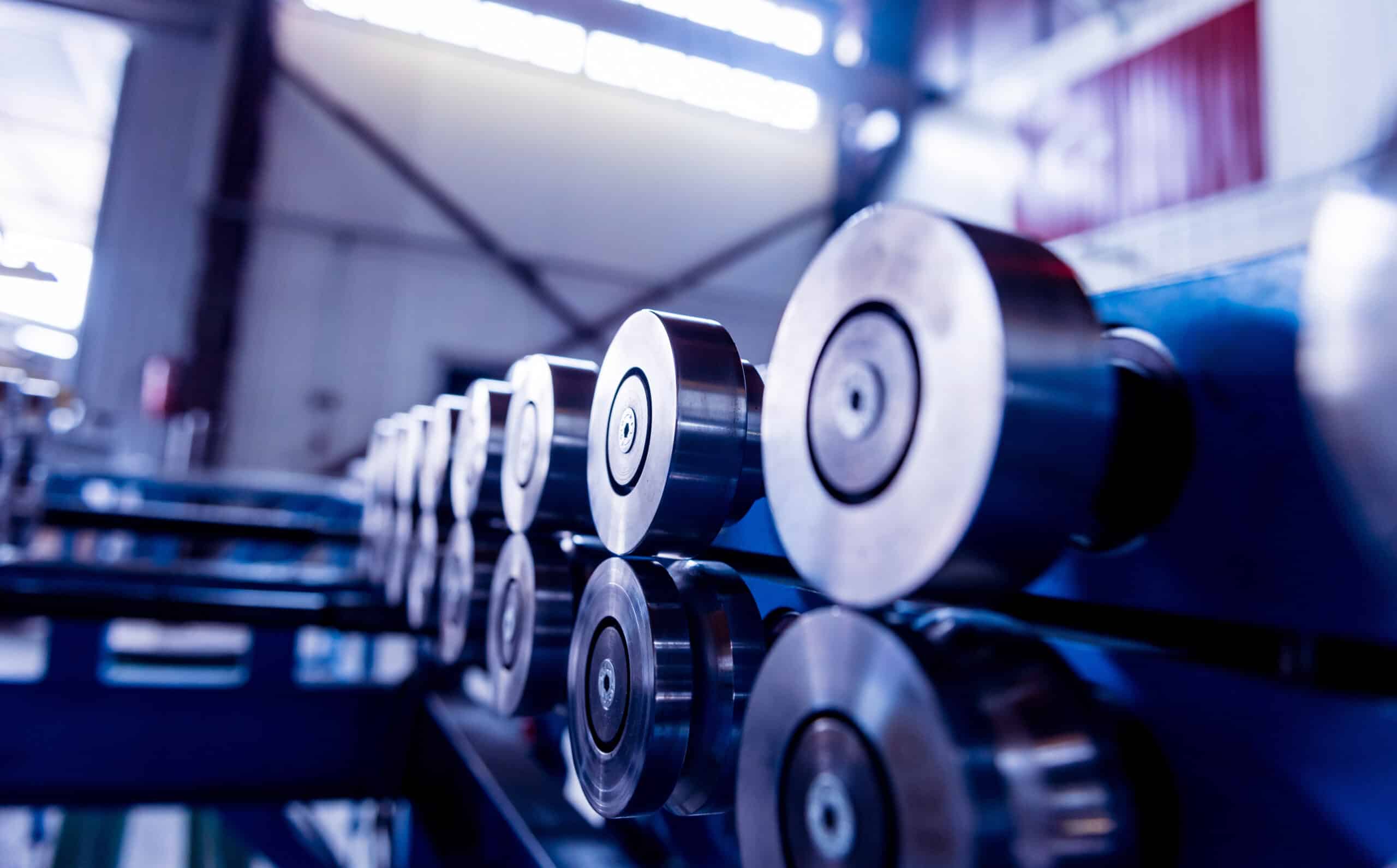

Specialized rollforming machinery, like Performance 1 from International Steel Framing, is crucial in creating standardized, high-quality components for pole barns. Performance 1 is designed to manufacture C-shaped steel sections needed for all facets of light gauge steel framing. The concept of this system is designed to maximize material output by eliminating change over time and keeping the training time to a minimum.

To automate and expedite every stage of the construction lifecycle, from truss design to fabrication, shipping, logistics, and installation, use KeyTruss, the cold-formed steel truss design system. Automation in steel truss design ensures consistency and efficiency, reduces errors, speeds up production, and lowers labor costs.

Automation software can generate step-by-step construction guides and manuals, helping contractors and DIY builders assemble the pole barn accurately and efficiently. Automation can also incorporate quality control measures, such as checking for precision in component measurements and ensuring that all materials meet industry standards.

Streamlining design, estimation, manufacturing, and construction processes can lead to cost savings for both contractors and customers. It reduces labor hours and the potential for costly mistakes. With the help of automation, pole barns can be erected faster than traditional construction methods. The combination of advanced automation software and specialized roll-forming machinery has made pole barn construction more accessible and efficient than ever before.

Want To Learn More About ISF Software and Maximizing Your Revenue?

We would love to learn more about your business and tell you how International Steel Framing has what you need to succeed in the cold-formed steel industry. Click here to learn more about manufacturing using Performance 1 Roll Former, ISF software suite, and KeyTruss.