A Little Bit of (Fun!) History

One of the first documented uses of cold-formed steel as a building material is the Virginia Baptist Hospital, constructed around 1925 in Lynchburg, Virginia. The walls were load-bearing masonry, but the floor system was framed with double back-to-back cold-formed steel-lipped channels. A site observation during a renovation confirmed that these joists from the Roaring Twenties are still supporting loads!

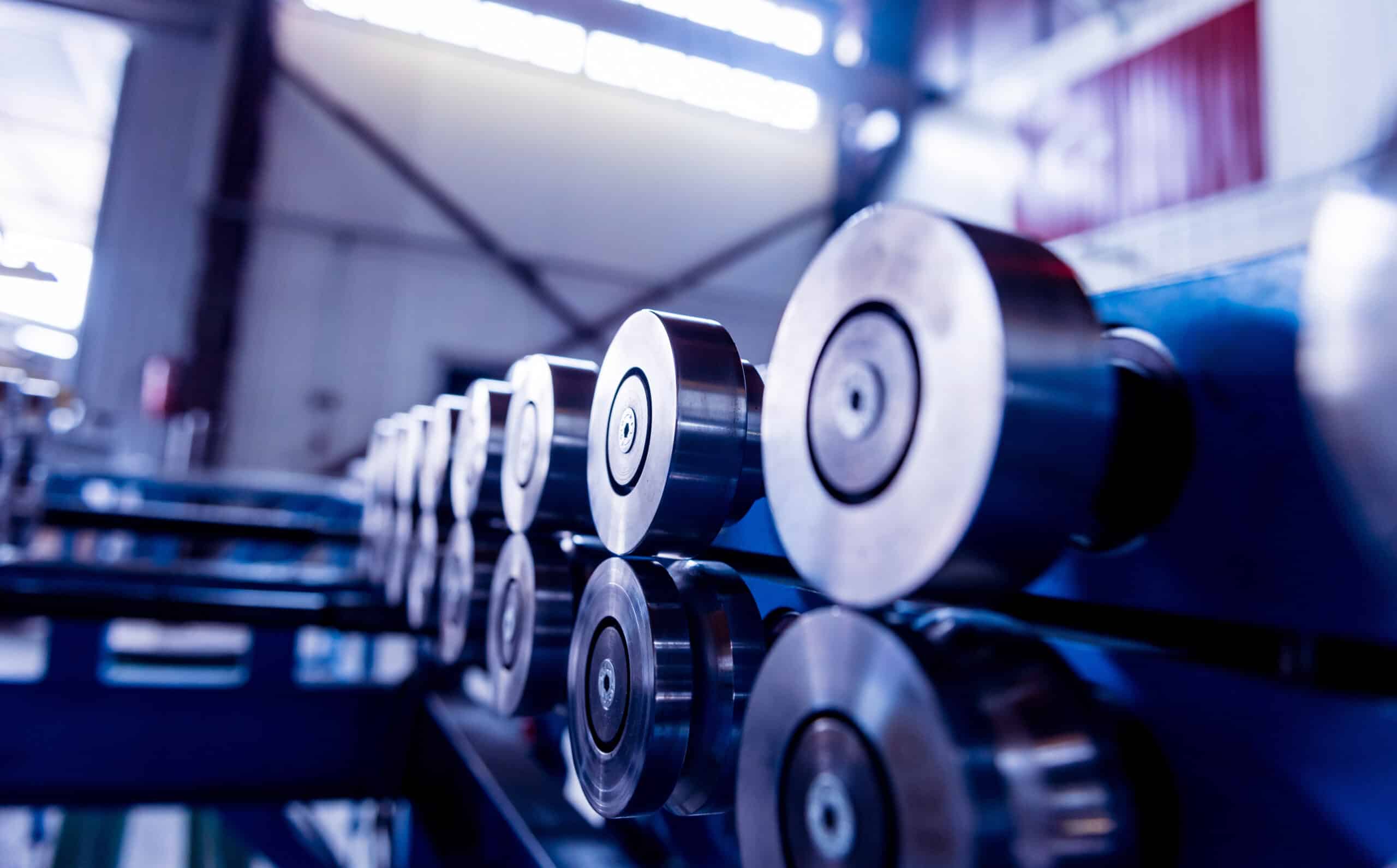

What’s the Difference Between Hot and Cold-Rolled Steel?

Cold-rolled and hot-rolled steel are two common forms of steel that undergo different manufacturing processes, resulting in distinct properties. With hot rolling, molten steel is pressed at extremely high temperatures, typically reaching or exceeding 1,700 degrees Fahrenheit. This process is quicker and less precise compared to cold rolling.

Initially, cold-rolled steel is exposed to high temperatures, like hot-rolled steel. Then, cold-rolled steel undergoes the additional step of being re-pressed using rollers after it has cooled down. This process results in a smoother and stronger final product.

Understanding the differences between cold-rolled and hot-rolled steel is vital for selecting the appropriate material for various applications—so let’s explore the properties of cold-roll steel versus hot-roll steel.

Surface Finish

Hot-rolled steel has a rougher surface finish due to scale and oxide layers forming during heating. Cold-rolled steel has a smoother surface finish with tighter tolerances. It is often preferred for applications with important aesthetics or stringent surface finish requirements.

Dimensional Tolerances

Dimensional tolerance is a range of acceptable measurements outside of the nominal dimension. Cold rolling allows for tighter dimensional tolerances and more precise shapes, making it suitable for applications requiring high dimensional accuracy. Hot rolling typically results in looser dimensional tolerances than cold rolling because it shrinks slightly during the cooling phase.

Strength

Cold-rolled steel tends to have higher tensile strength and hardness than hot-rolled steel. Statistics show cold-rolled steel is about 20% stronger than its hot-rolled counterpart. This is due to the strain hardening during the cold rolling process. Hot-rolled steel generally has lower tensile strength compared to cold-rolled steel.

Workability

Cold-rolled steel is often preferred for applications requiring precise forming and bending, as it retains its shape better and has less spring-back than hot-rolled steel. Hot-rolled steel is easier to work with in forming and welding, especially where tight dimensional tolerances are not critical.

Environmentally Friendly

Like all steel products, cold-formed and hot-formed steel are highly recyclable, making steel an environmentally friendly material choice. Steel framing is made from an average of 67% recycled material. And, since steel itself is 100% recyclable, steel construction aids in obtaining LEED certification. In addition, steel homes and buildings have significantly fewer toxins to irritate asthma and allergy sufferers.

Applications of Cold-Roll and Hot-Roll Steel

Cold-formed steel members are widely used in building construction due to their high strength and stiffness-to-weight ratios, ease of prefabrication, and mass production.

Cold-roll steel applications:

- Residential and commercial structures

- Aerospace structures

- Home appliances

- Metal furniture

- Strips, rods, bars, and sheets

- Mechanical Components

Hot-roll steel applications are:

- Agricultural equipment

- Automobile parts (frames and wheel rims)

- I-beams

- Railroad equipment (tracks and railcar components)

When assessing steel choices for a project, it’s important to consider that certain materials may be more suitable than others for specific purposes. Knowing which type of steel provides the appropriate properties for a particular application can help avoid excessive spending on raw materials and streamline the building process.

Ready to Utilize Cold-Formed Steel?

International Steel Framing is the leading single-vendor solution for everything needed to succeed in the cold-formed steel industry. Contact us today to learn more.